No products in the cart

Gen 3: Replace Pressure Gauge

Time: 15 minutes

Tools:

- 15 mm wrench

- crescent wrench or channel lock pliers

- 5/16″ nut driver

- Teflon tape

- snip for zip tie and small zip tie

- paper towels to blot concentrate

Parts:

- Replacement pressure gauge kit, including adapter rings (#10978)

- straight female connector 1/4″ Threaded x 1/4″ PTC (# 10119)

1. Remove bottle. Reposition controller and shroud. See Gen 3: Access Components by Repositioning Shroud.

2. Remove existing pressure gauge

A. Cut zip tie securing flexible tubing to coupler. Put on latex gloves and remove tubing. Allow concentrate in tubing to drain onto paper towel.

B. Remove 1/4″ nylon tubing from fitting on pressure gauge and remove shroud from unit.

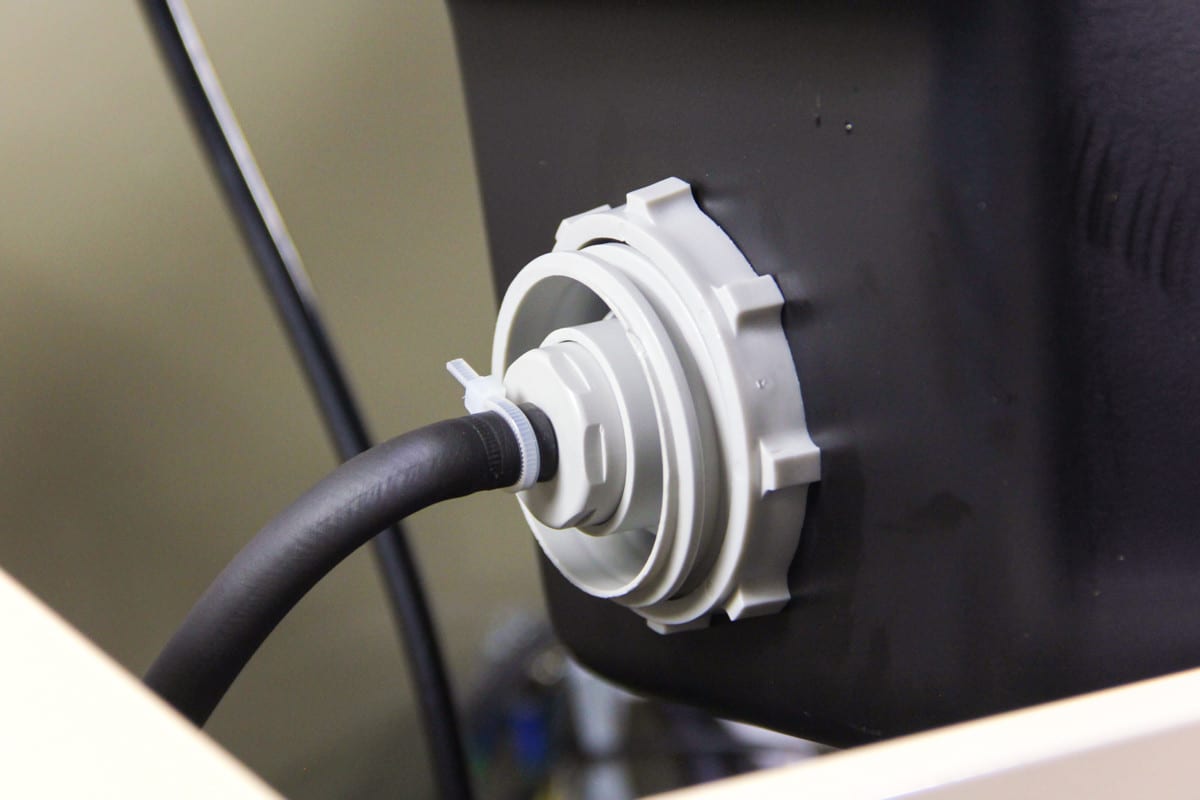

C. Using channel locks or crescent wrench and 15 mm wrench, remove straight female connector as shown.

D. Using 5/16″ nut driver to remove nuts securing gauge to bracket, and remove the gauge from shroud.

3. Install replacement gauge

A. Wrap teflon tape around threads on gauge.

B. If the diameter of the failed gauge (and the hole it was mounted in) is the same size as the new gauge, proceed to step 3D. if not, you’ll need to use the adapter rings.

C. Slide one of the adapter rings over the gauge, then insert the gauge into the hole, so that the ring is between the gauge and the top side of the shroud. Slide the other adapter ring over the gauge, sandwiching the gauge between the two rings.

D. Position the bracket on the back of the gauge and then tighten the straight female connector to the gauge.

E. Ensure the gauge is oriented correctly on the top side of the shroud, then tighten the nuts securing the gauge to the shroud.

F. Place shroud with new gauge on left side of unit and reconnect 1/4″ nylon tubing to gauge. Make sure it is secure in the fitting.

G. Reconnect flexible tubing that feeds dosing pump to hose barb on coupler and secure with zip tie.

4. Return shroud and controller to original position. See Gen 3: Access Components by Repositioning Shroud.